Andy re-creates the iconic photo of 20th century construction

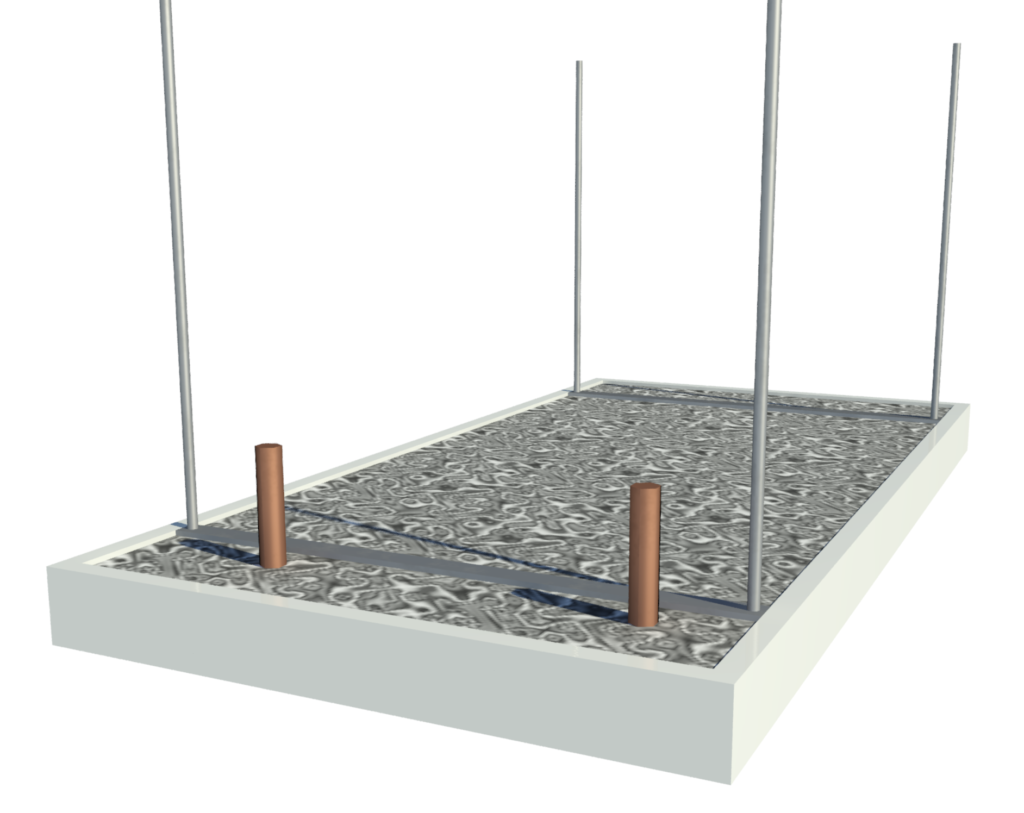

We always try to keep testing our Revit families in different environments over time to ensure optimal performance. Our Revit entourage family, Andy, is no exception.

We always try to keep testing our Revit families in different environments over time to ensure optimal performance. Our Revit entourage family, Andy, is no exception.

In case you’re one of the 99.99% of people out there who’ve never heard of a chilled beam, let me briefly introduce this obscure-but-mighty piece of mechanical equipment.

In our last post, we shared a generic Revit family we created for a non-condensing fire tube boiler.

We recently completed a new generic family for a non-condensing fire-tube boiler.

As a Revit user or BIM Manager, you’ve probably had people ask you about “LOD” or “Level of Development”.

In the past months, we’ve been working closely with consulting engineering firms to produce families that work with their shared parameters.

You can tell a lot about people by watching what happens on an escalator.

Now that the holidays are over and we’re back at work, it’s time to capitalize on that last drop of holiday spirit and get cracking on our New Year’s resolutions!