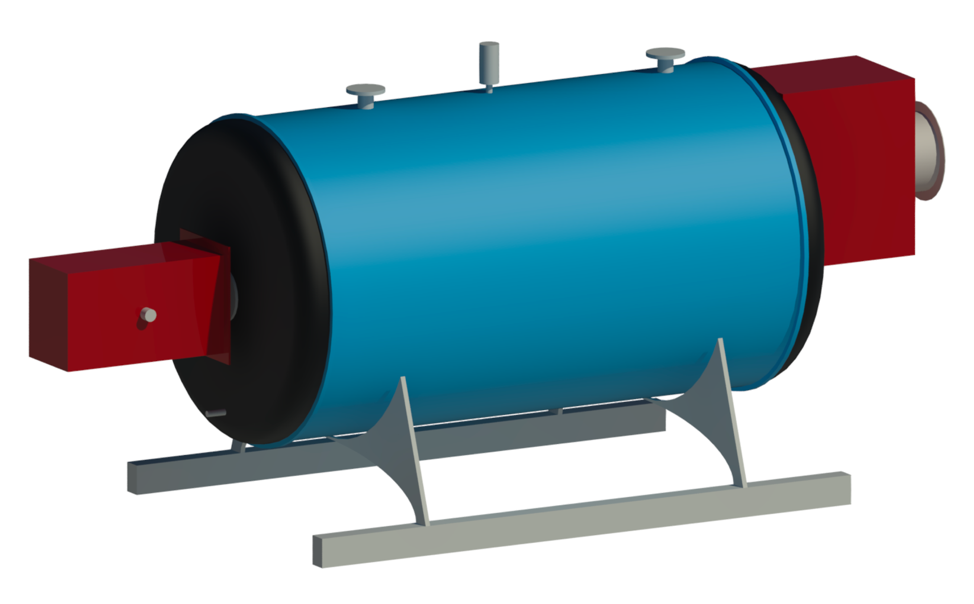

We recently completed a new generic family for a non-condensing fire-tube boiler. While non-condensing boilers are not as efficient as condensing ones, there are still plenty of them around for reasons such as legacy usage, lower cost and simpler maintenance.

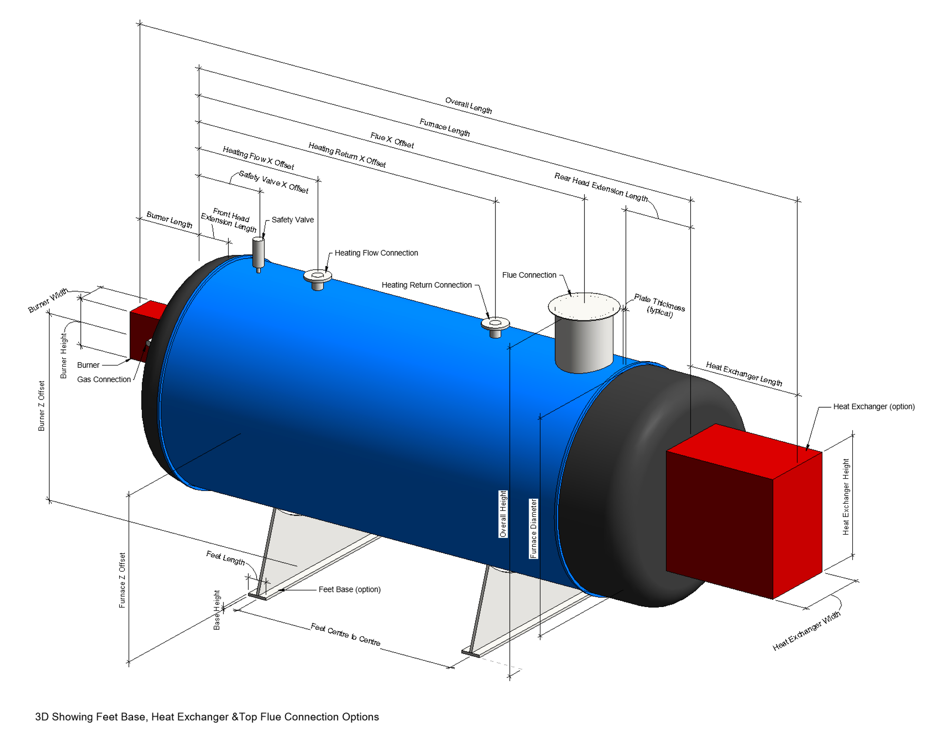

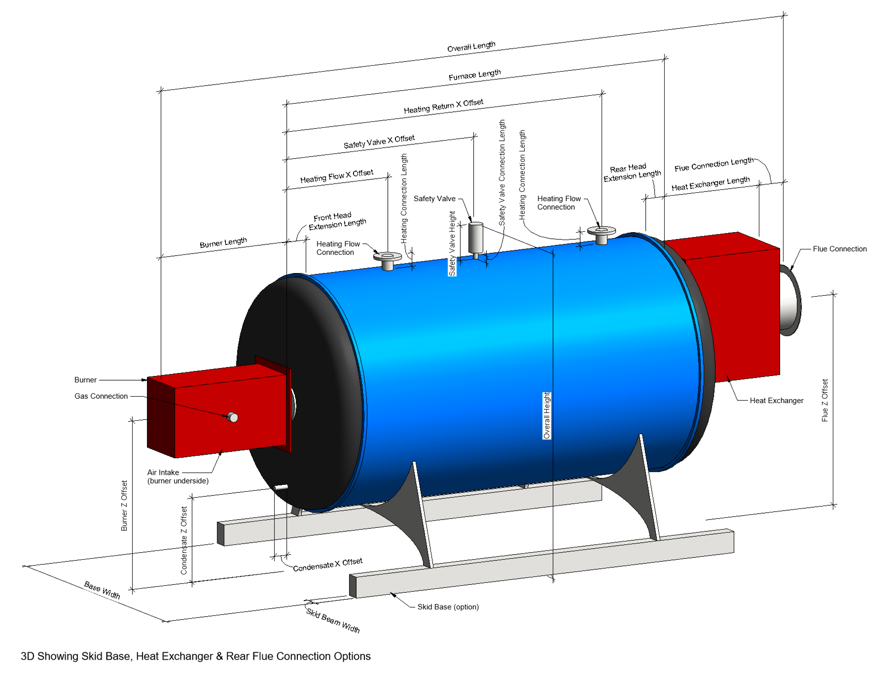

The Revit family for this particular boiler configuration has a standard burner, optional heat exchanger and options for either a skid base or feet base. We modeled it based on units from manufacturers such as Babcock Wanson, Hoval, Cleaver Brooks and Cochran.

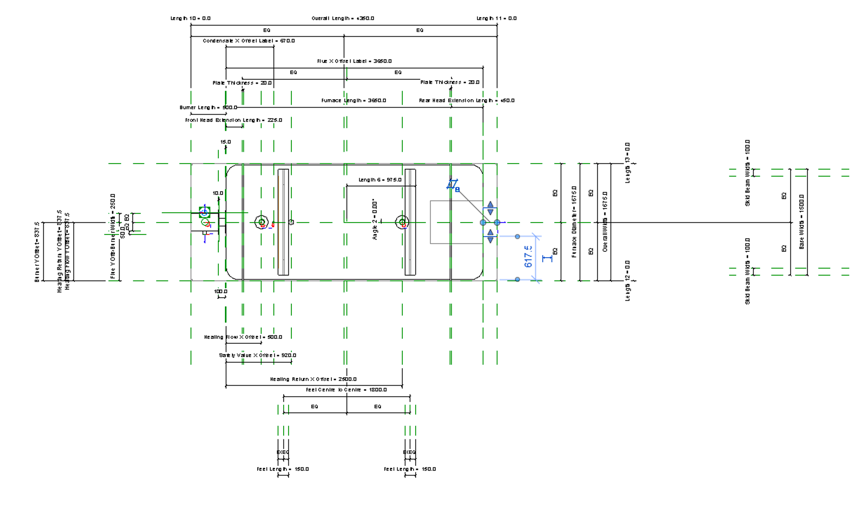

We built the geometry so that all of the unit components – heat exchanger, burner, base, connections and the main shell – can be modified to suit a large range of manufacturer specifications. The main shell’s furnace length and front/rear extensions lengths are fully flexible. The position of the burner and heat exchanger on the main shell can be changed, and the heating connections and safety valve can be positioned anywhere on the top of the unit along its centerline.

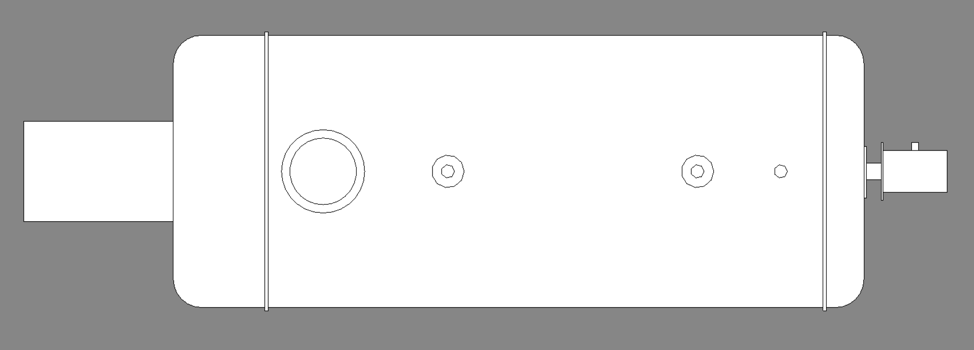

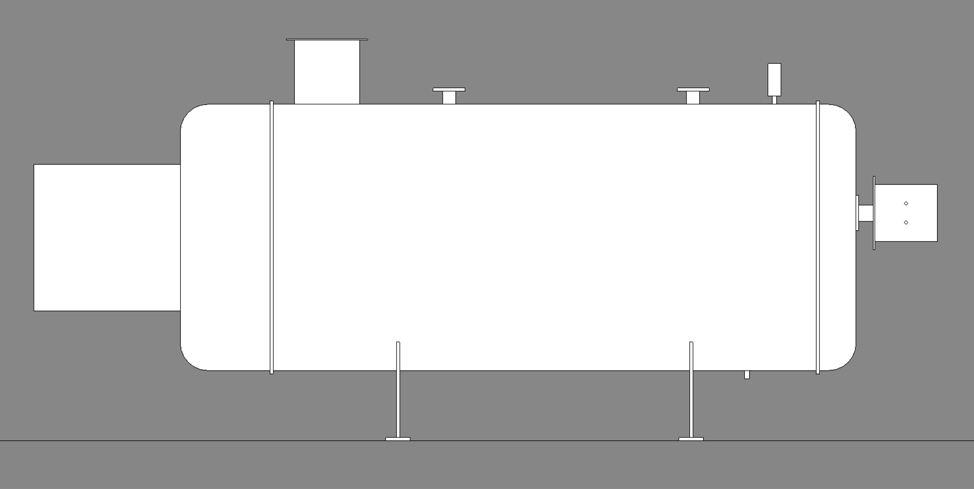

MEP connections can flex to any size within reason, and the pipe flange dimensions, while controlled using formulas, can be replaced with a lookup table if required. The family construction options also allow the drain and flue connections to be moved around. As always, our family has three levels of detail in 3D and 2D, with the 3D geometry restricted to showing in 3D views only. It includes separate 2D geometry for plan and elevation views, allowing the user to move and work faster in Revit’s 2D views.

The family’s parameters have been structured to facilitate easy configuration and modifications. Parameters controlling the visibility of model options are located under the Construction group, and parameters controlling dimensions and positioning are located under Dimensions. While the model can flex to a wide range of manufacturer specifications, in cases where additional modification is necessary to match a desired unit, you will find the parameters that control formulas driving the family geometry grouped under Other. The family also contains the full set of CIBSE PDT shared parameters for a non-condensing boiler.

We’ve set all unit options as type parameters except for “Clearance Zone”, which is located under the Constraints group. The family’s options include:

- Clearance Zones – When selected, this activates the Clearance Zone geometry in 2D & 3D. The clearance geometries have been assigned to a “Clearance Zone” subcategory, giving the end-user more control over how they appear in a project.

- Condensate Front Connection – Moves the condensate drain connection to the front of the unit.

- Condensate Bottom Connection – Moves the condensate drain connection to the bottom of the unit.

- Heat Exchanger – Activates the heat exchanger before the exhaust flue connection.

- Skid Base – Activates the skid base option.

- Feet Base – When Skid Base is not selected, this will automatically turn on.

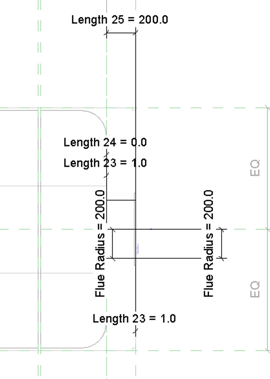

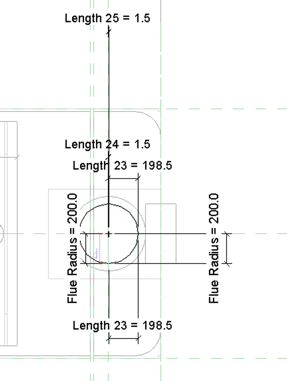

- Top Flue Connection – Moves the flue connection from the back of the unit to the top.

In families such as this, where there are multiple detail items for the geometries, we try to combine them in order to save file size and reduce complexity. An example of flexible masking region can be seen in the top view for the flue connection shown below. The flue connection can move from top to rear positioning. Instead of two separate masking regions for each scenario, we used a series of lines, ellipses and parametric lengths to reflect a square or round profile.

This boiler family has been created as non-hosted mechanical equipment in metric units. It has one exhaust air duct connector for the fumes, a condensate drain connector, hydronic supply/return connectors for the hot water flow and return, a connector for the gas, electrical connectors for power and controls, and conduit connectors for power and controls as well. The family has seven material parameters to control the appearance of all major geometries, such as base, shell, extensions, MEP connections, burner and heat exchanger.

All in all, our generic non-condensing boiler family has the flexibility and options to provide plenty of shelf life for your Revit heating system library.