In our last post, we shared a generic Revit family we created for a non-condensing fire tube boiler. To continue on the same theme, we decided to showcase another piece of generic mechanical equipment content serving hot water: the water storage heater.

A water storage heater differs from a boiler in that, as the name suggests, it stores the hot water in addition to heating it. Water storage heaters can directly heat the water, meaning they have their own source of heat, such as the gas connection in this family. Or they can have indirect heating, which means they get heat from another source such as an existing low temperature hot water system. The direct water storage heater shown here is based on manufacturer-specific units from Lochinvar, Hoval, Hamworthy, Dorchester, Platinum Water Heaters, Andrews Water Heaters and GSW.

For maximum control over visualization, the family has three levels of detail in 3D and 2D, with 2D views showing only symbolic lines and masking regions for optimal project performance. It also has seven material parameters to control the material assets for all of the major geometries, including the main body, gas control valve, piping connections, base and additional highlights.

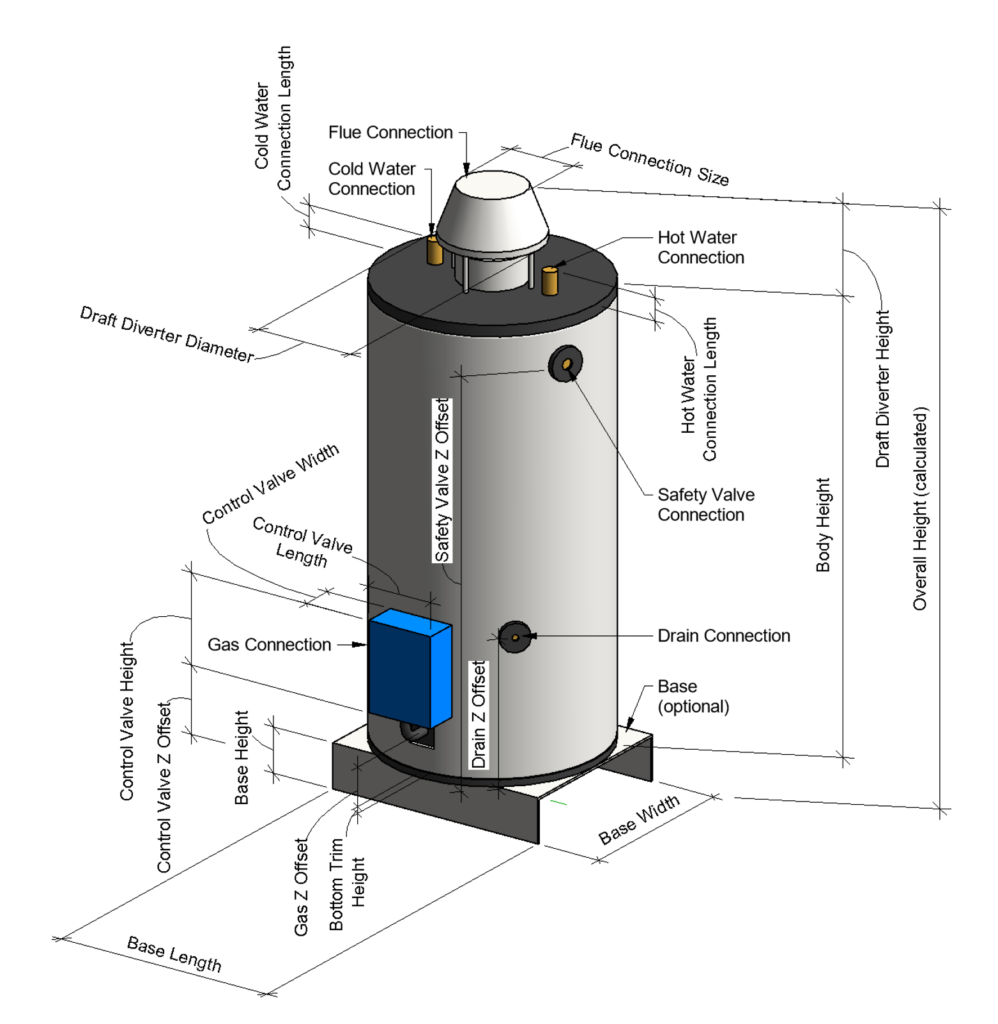

As you can see in the image above, we’ve created all of the major geometries parametrically so that they can be sized as needed and controlled independently from each other. Offset locations have also been given parametric controls.

Our water storage heater contains two options for clearance zones and the base. The clearance zones option will toggle clearance geometry in 2D and 3D. We’ve assigned the clearance geometry to its own subcategory in order to give the end-user further control over visualization.

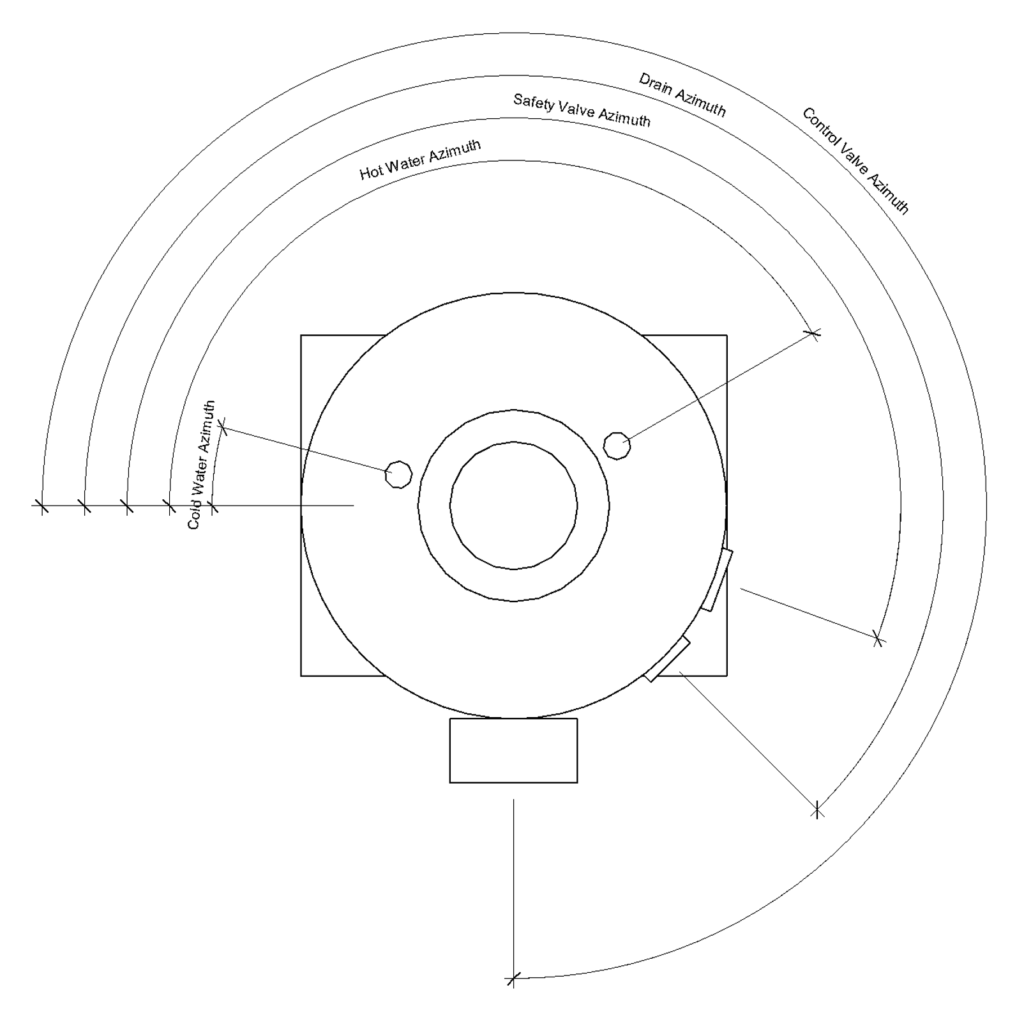

The family has four piping connections for the gas in, cold water in, hot water out and safety valve. It also has one duct connector for exhaust air out and electrical connectors for power and controls. All of the connectors, including the control valve, can rotate from 0 degrees to 360 degrees, and the overall width and length of the unit will adapt to suit the angle and dimensions. The four piping connections can also change size and length.

Each one of the pipe connectors and the gas control valve are hosted on independent reference lines, allowing them to fully rotate around the unit as well as move vertically to any offset. The base is also independent of the body and able to change to any size. Providing this level of flexibility meant there were at least five factors that could affect the overall width and length of the unit. This is a problem for clearance zones and coordination of MEP services, as well as any structural model if the water storage heater is placed on a concrete plinth.

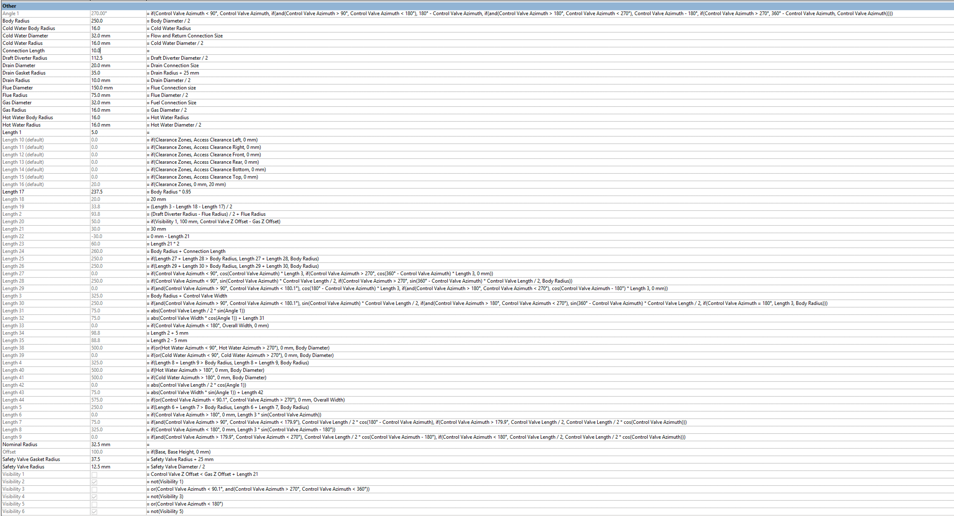

Our families will always have parameters with formulas to control the flexing and impact of options and dimensional values. However, this family has more background work than others. In order to make sure that the overall dimensions would adapt properly to the flexibility of the connectors and base, we had to use a number of trigonometry formulas to cover all the different scenarios. We then added a bunch of controlling formulas to manage which of the options, values and azimuth will have the greatest impact on the outer dimensions of the unit.

This kind of work is something that’s beyond the average Revit user and that would be an impractical use of resources for most design firms. We push the extra mile so nobody else has to.

Family Stats

File Size: 616 kB

Revit Version: 2017

Category: Mechanical Equipment

Hosting: Non-Hosted

Units: Metric

Type Catalog: No

Types: 1

Levels of Detail: Fine, Medium and Coarse in 3D and 2D

Options: Clearance Zones, Base

Omniclass: 23.75.10.11.24 / Heat Generators, Thermal Liquid

Manufacturer: Generic